Plant tours are part and parcel of brand trips. So when we were told that after the iX3 Neue Klasse launch in Munich, BMW would fly us out to Debrecen in Hungary to get a preview of BMW Group Plant Debrecen, where the new iX3 was built, we thought that this would be your run-of-the-mill itinerary. A carmaker wanting to show off its newest and latest plant is nothing new, of course, but what we could not imagine was just how wrong we would be, and just how significant BMW’s plant in Debrecen would be for its people and the city.

Upon landing in Debrecen International Airport, a two-gate facility that was about half the size of Boracay’s airport, it was clear we weren’t in Germany anymore. Debrecen is Hungary’s second-largest city, but only has a population of roughly 204,000.

You know that feeling when you are so proud of something that you can’t wait to share it? That’s what it felt like watching the citizens of Debrecen ushering us around their city. You could feel the pride they had, for their town and its BMW investment. Our plant visit didn’t start until the next morning, but our arrival was a whirlwind orchestra of a tour, a great welcome dinner, and a speech by the mayor of Debrecen himself, Dr. László Papp.

The 400-hectare Debrecen plant was the most advanced and newest plant in the BMW network, and while it was announced way back in 2018, it took seven years for the factory to start churning out the Neue Klasse iX3.

Some kinks are still being worked out, but series production of the newest BMW EV will kick-off in October this year. Read on to hear how one decision forever changed the destiny of an entire city, and by extension, a country.

Foreign direct investment changed Debrecen for the better

Debrecen is a peculiar place. For the second largest city (and twice in its history, the capital) of Hungary, it has a fraction of the population of Budapest, the current capital. In fact, before BMW set foot in Debrecen, the city had a problem with a dwindling population, as its residents moved to other parts of the country to find jobs.

Then BMW came in; and in just seven years since announcing the construction of the Neue Klasse plant, the population decrease was actually reversed, growing for the first time since the decline started.

Since the injection of direct foreign investment, city revenue grew four times higher as BMW and other investors pumped in around 12 billion euros (P809 billion). This resulted in the creation of about 21,000 new jobs for the residents of the city, which is insane when you think about the total population. This means that 10% of the residents work for the foreign companies that set up shop in the city, with the largest employer, and by far the biggest investor, being BMW.

Since then, Debrecen has been ranked number one in the EU for foreign direct investment strategy, and has even reached the top 10 in the 2021 worldwide ranking (against cities like New York and Hong Kong).

A car plant includes more than just the plant itself

The mayor called BMW, “a responsible partner and good neighbor to the city,” and neighbors are the name of the game as a car plant cannot stand alone. Suppliers sprouted up all around the industrial zone of the plant in order to support the automobile manufacturing operations. From a battery producer to tire suppliers and other accessories, all of these plants opened up to facilitate the zero inventory, just-in-time production system employed at BMW Debrecen. This allows the industrial landscape in and around the city to be hyper diversified, with jobs opening up in multiple factories, under different multinational companies. This means one thing—more jobs, and more income not just for the city, but the residents thereof.

It’s more than just investing in a city, it’s investing in the people

We were told that the first facility that BMW completed in the plant was its learning center. This clearly shows the outward intent to prioritize knowledge transfer and education for the workers of the plant. In fact, BMW had partnered with the city’s educational institution, the University of Debrecen, to launch new training programs, as well as new research programs in the university.

Not only that, but BMW also started a vocational program in the plant, catering to about 300 students. This influx of opportunities increased the number of students in the University; more than 10,000 new students just in the last 10 years.

Investing in a long-term partnership with educational institutions goes both ways; this allows BMW to train and hire the next generation of workers, at the same time provide career paths to those who have chosen to come back to the city to make it their home again.

Finally, since the plant is completely integrated into the BMW network, once you work for the Debrecen facility, you can easily be brought to any other Neue Klasse plant for immediate and effective knowledge transfer and upskilling, as all the new plants of BMW are twins of each other, with the same processes, standards, and layout.

BMW’s focus on people over robots/automation is a different but welcome direction

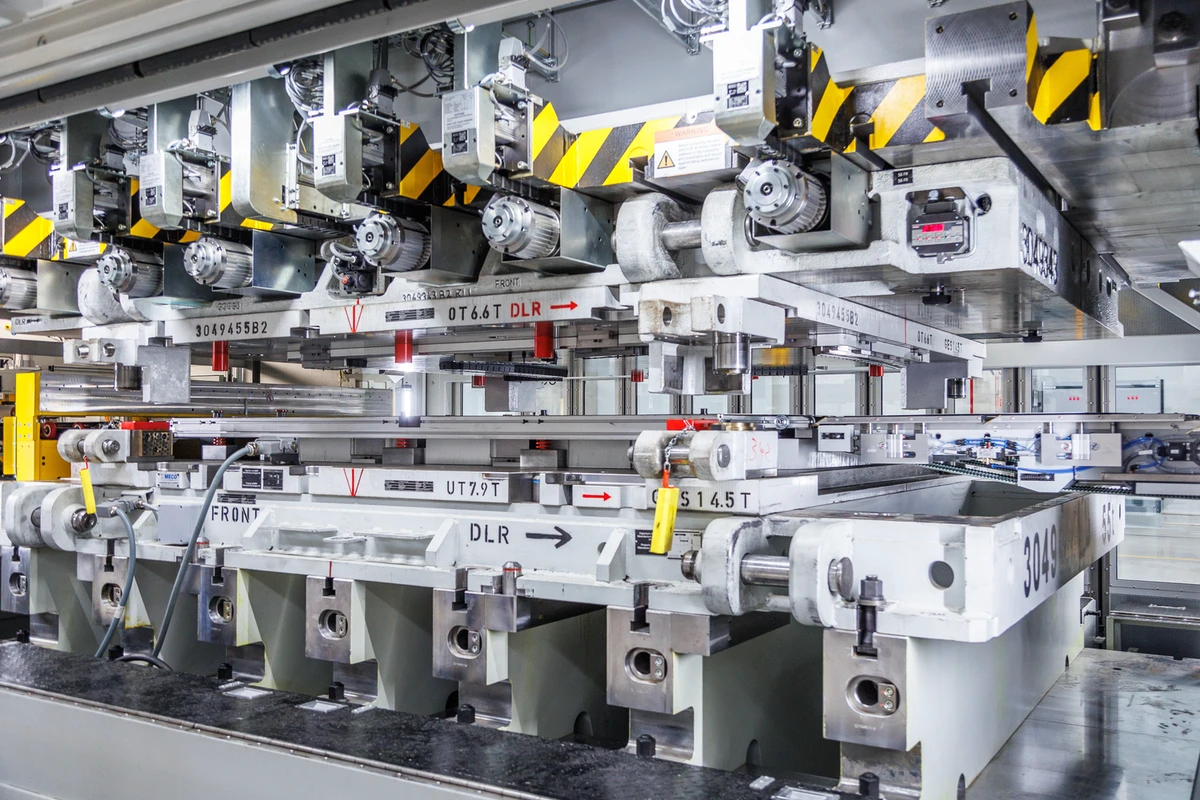

As we made our way around the massive facility with a floor so clean you could eat off of it, we saw a lot of people taking part in the assembly of the cars. While other plants constantly brag about just how much automation they have, BMW explained that it only had 20 robots in the assembly line, and this intrigued us.

When asked about this, they told us that robots are a permanent fixture, and they wanted to be nimble when it comes to producing the Neue Klasse (so nimble that up to just six days before your car comes off the line, they can still change all the specifications of your vehicle). So not only does more people mean that production can be nimbler and more flexible, but also that more jobs are available, which results in an overall larger talent pool that just happens to be much more flexible in terms of production adjustments.

These people effortlessly (thanks to electric and pneumatic assistance) move parts around and are all empowered, even encouraged, to stop the line at any time to do a root cause analysis in case of any defects. The main goal is zero defects in an iX3 rolling off the line.

This level of empowerment, especially with a car production rate of 30 units per hour, or 150,000 iX3s a year, is very impressive. It just goes to show the faith BMW has put in its people over machines and automation.

It does not have to come at the cost of the environment

Despite the plant’s technological marvels in assembly, it’s the paint shop that might just be the most impressive part of the plant. Normally, the paint shop is the most energy-intensive part of a car manufacturing facility, and this is mainly because of the ovens and high temperatures needed for effective painting and drying. This normally requires a lot of fossil fuel use. So how does this BMW plant achieve all this with zero fossil fuels?

They decided to make the paint shop completely electrical. With all the energy for this massive facility coming from water, sun, and wind, no fossil fuels are burned to power the Debrecen plant. The paint shop alone, just from the fact of being electric, saves about 12,100 tons of CO2 per year, while the rest of the plant was designed from the ground up to minimize CO2 emissions. This required a lot of proprietary technological development, as the typical gas-powered ovens and heaters were all replaced with electrically powered and non-fossil alternatives.

To further support this, BMW allocated 50 hectares of the property (on the ground and on roofs) for its own solar powerplant on site, which includes hail-proof solar roofing to cover the parking area for finished vehicles.

Not only that, but to promote this as a green facility, BMW planted around 8,000 trees, resulting in about 85 hectares of green land with various flora and fauna preserved.

This shows that the commitment is not just to build cars, but to do so sustainably, and in effect protect the very land that the plant was built on. This doesn’t even take into account all the recyclable materials that are being used in the iX3, with seat covers made from plastic bottles, and the frunk insert made from locally sourced discarded fishing nets. It is a holistic approach, which is the best method by which one can achieve net zero (which BMW commits to hit by 2050), which comes with very tangible benefits for the country.

The Philippines can only dream of such an investment (for now)

This plant has changed Debrecen for the better. It opened up jobs and opportunities for their citizens, and increased the quality of life for them while strengthening their middle class. It is a long-term investment in a country and its people, and we can only hope that one day we can be fortunate enough to receive a similar blessing.

If that day comes (and we hope to be there when it does), such an investment would change many lives, and hopefully make us proud that someone likes BMW decided to call the Philippines a home. Until then, we can only hope (and be slightly envious of Debrecen).