It’s another mundane workday. You settle into the driver’s seat, turn on the ignition, and start the car. The starter motor cranks, but the engine won’t fire up. Uh oh. There might be a dozen reasons for this annoying car problem, but it could be distilled into the absence of any of these: fuel, spark, or cylinder compression.

Here’s a step-by-step approach to finding and fixing the problem:

1) Check your fuel.

Do you have a functioning fuel gauge, some fuel inside the tank, or, more important, the right kind of fuel? The gasoline station attendant may have accidentally filled your tank with diesel.

2) Make sure you have spark.

Find the fuel system fuse and take it out of its socket. It should be in a fuse box together with the fuel pump relay. Pull out a spark plug wire, and jam a screwdriver with an insulated grip where the spark plug attaches. Hold the other end of the screwdriver close to but not touching a grounded metal surface. Have an assistant or a companion crank the starter. An electrical spark will jump in the air gap between the ground and the screwdriver attached to the plug wire. If there is none, check the whole ignition system from the plugs, plug wires, ignition coil, and cam position sensor. If the vehicle is equipped with neutral safety and/or anti-theft systems, make sure they are deactivated.

3) Inspect your starter motor.

A failing direct current motor may be kicking over but will be drawing out too much amperage, so even a good battery may not supply enough cold cranking amps. Your battery wires and terminals may feel warm or hot because the starter motor is pulling out high electrical currents.

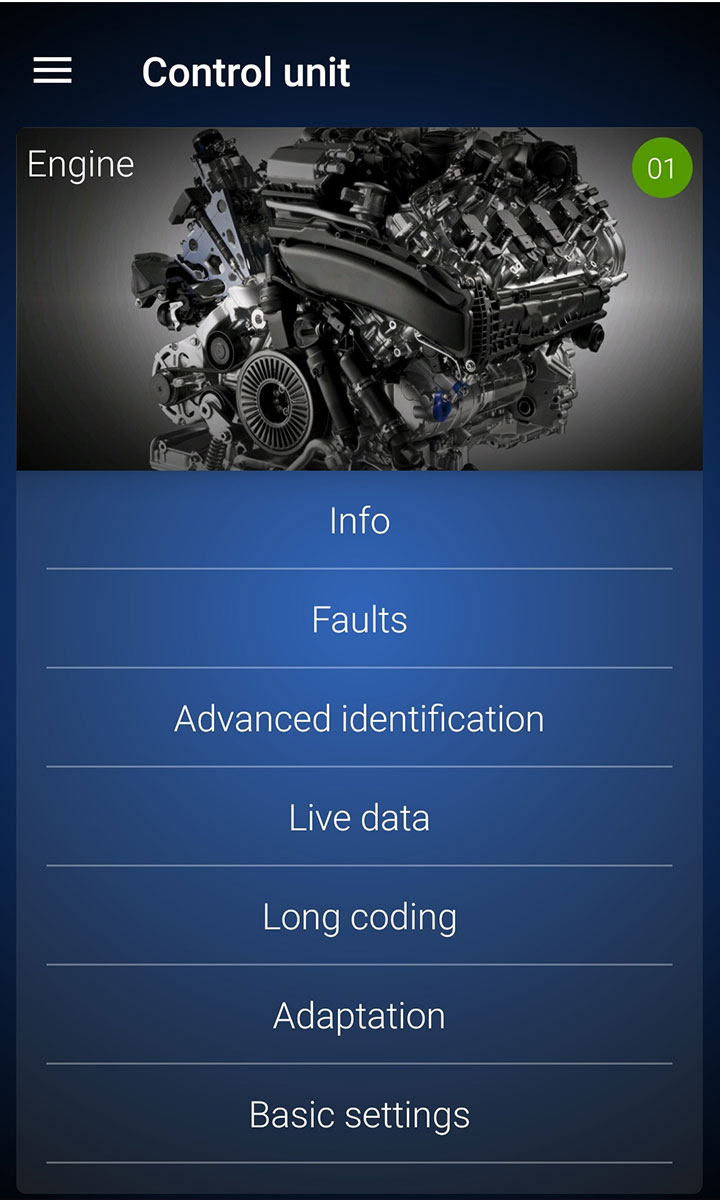

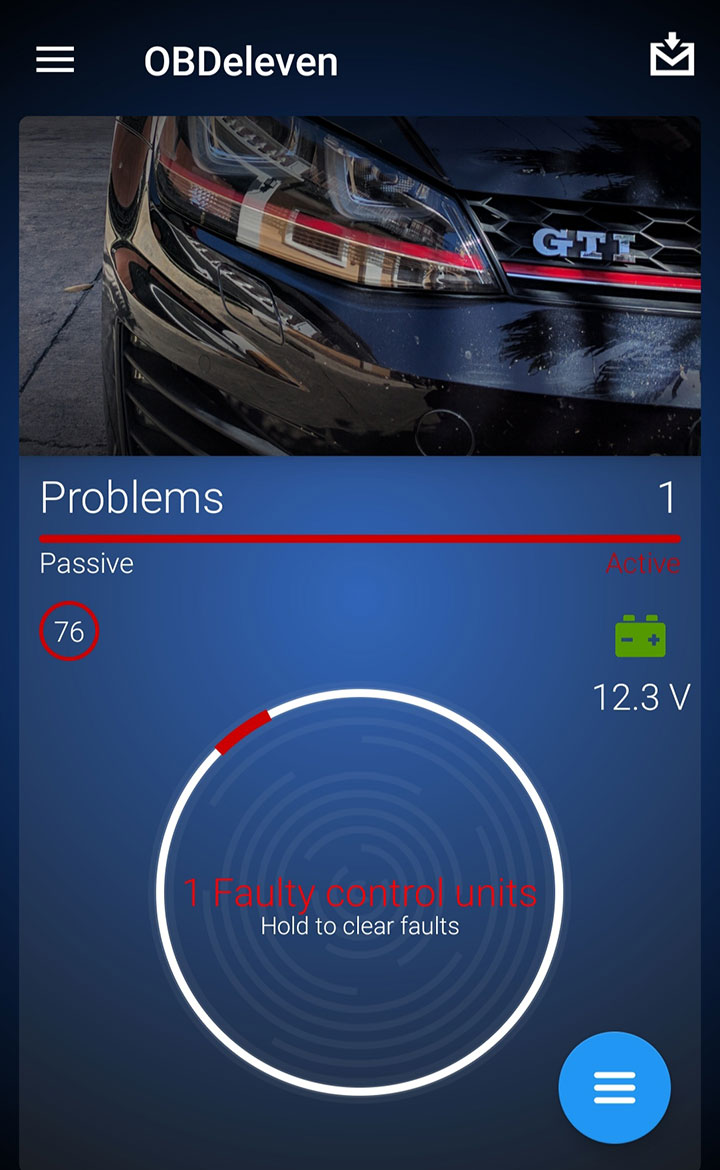

4) Scan for diagnostic fault codes.

If the dash shows a glowing check engine light, an OBD scanner is a handy tool to have. It may reveal a number of fault codes related to fuel pump errors, ECU faults, cam/crank position sensor, or fuel pressure problems. If your OBD scanner is sophisticated enough, it can provide live data from the ECU. Fuel pressure readings, voltage supplied to the pump, coil-on-plug individual voltages, and other valuable data are viewable from your laptop or smartphone screen. The OBD scanner provides enough info, in fact, that you may skip the following diagnostic tests.

5) Check for compression.

When you don’t have a scanner, and after confirming that the ignition system is working, open the valve cover and check the timing belt or chain. If it’s intact and everything looks okay, the crank should be turning and timing cylinder compressions as it should. You’ve pinpointed the problem to lack of fuel.

6) Check your fuel system.

Upon turning on the ignition, you should hear the fuel pump in the tank humming and the fuel pump relay clicking. If you don’t hear both, check the fuel system fuse which you removed earlier when checking for spark. An intact fuse and a clicking relay will have isolated the problem to the fuel pump. Depending on the car type or model, the pump and the tank should be accessible from under the car or under the rear passenger seats. Visually inspect the electrical connectors for corrosion, and, with a multimeter, check for continuity and voltage supply to the pump.

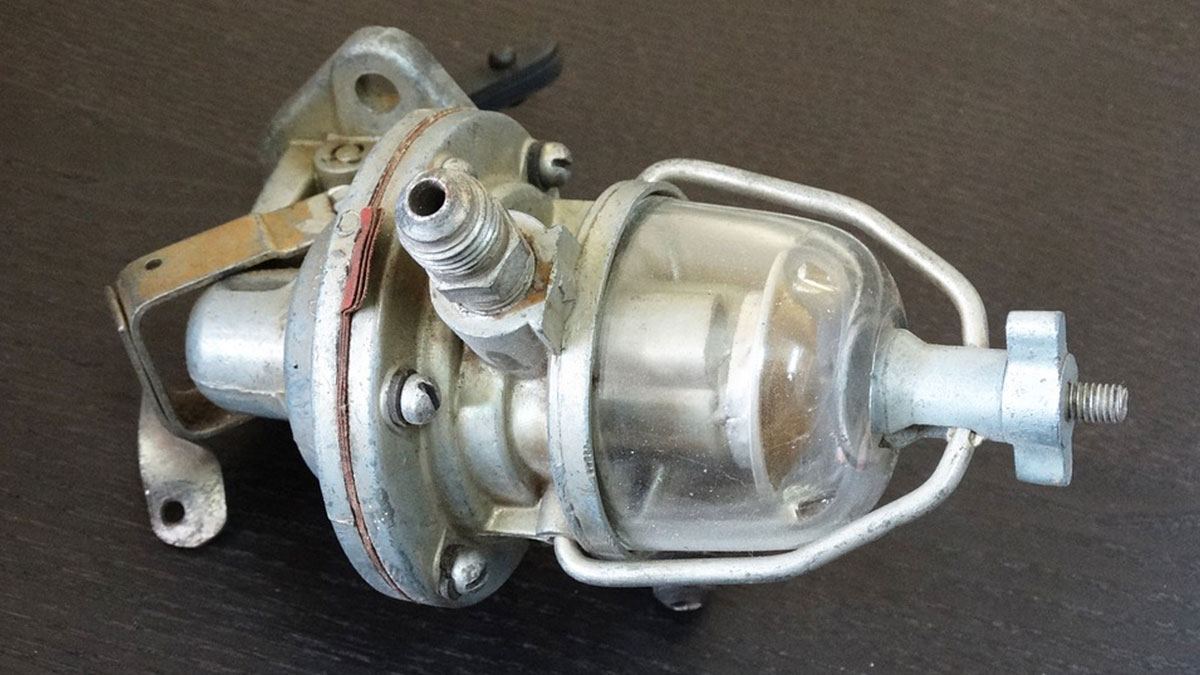

7) Confirm if you have fuel pressure.

From this point onward, you’ll be directly handling fuel. It would be wise to wear safety goggles and gloves, and to collect spilled fuel in a sealed container. With a pressure gauge tapped into the fuel supply hose close to the injectors, turn on the ignition and crank the starter. The fuel pressure should progressively rise to about 20-30 pounds per square inch (psi). If it rises sluggishly, your fuel filter is clogged. Taking the filter out, replacing it with a new one, or bypassing the filter will give you a normal fuel pressure reading.

8) Pull out the pump.

Remove the fuel pump from the tank to bench-test it further or replace it. Hook the electrical connectors to a power source to confirm pump operation. Take care not to cause a spark and work in a well-ventilated area to avoid igniting the gasoline fumes.

9) Replace the pump.

Most fuel pumps have no serviceable parts and are relatively cheap to replace. Buy an original equipment (OE) manufactured pump or upgrade to an aftermarket one, making sure the replacement is compatible with your vehicle. If you’re unsure of the fuel quality or if you find significant loose rust, drain out all the gasoline and clean the tank.

10) Reset fault codes.

After reassembly, refill the tank with fresh fuel and start the car. With the scanner, you can erase the stored error codes to turn off the check engine light.