When Nissan announced that it was going to put a variable compression engine on the market, the reactions ranged from "Oh, wow!" to "It's never going to work." But Nissan's clever new technology has a lot going for it. Yet before we tackle how that engine works, first we need to review how internal combustion engines make power.

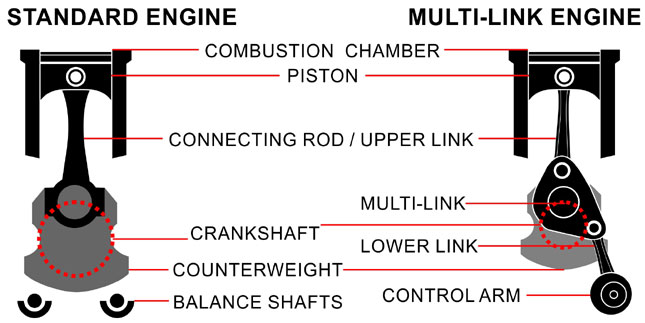

Engines move a car by rotating a crankshaft, which transmits power to the wheels. Think of a bicycle crank, except with burning fuel instead of muscles powering it. Ignition inside the “combustion chamber” causes the fuel and air mixture inside to burn rapidly—or explode in slow motion, if you will. This expansion pushes down a piston, which pushes on a connecting rod, which rotates the crankshaft, and through that repetitive rotation power is sent to the wheels. This is called the power stroke. As the crank rotates, it pushes the piston back up, just as a rotating bicycle crank pushes your leg back up, this pushes the burnt air and fuel back out the exhaust valves. This is called the exhaust stroke.

The compression ratio of an engine helps dictate power and fuel economy. A typical engine has a compression ratio of 10:1, in which the air and fuel is squeezed to 1/10th its normal volume. Like squeezing a balloon, the greater the compression, the bigger the bang. High compression ratios also make for a cleaner burn, as the fuel and air are concentrated in a smaller space, they burn a lot more completely.

However, when you use a turbocharger, as Nissan does with its “Variable Compression Turbocharged” engine, you're already pumping a whole lot of extra pressure into the combustion chamber. This makes for more power, but the extra pressure can cause the air-fuel mixture to heat up too quickly and explode prematurely. Needless to say, this is very bad for your engine, which is why turbocharged engines typically use lower compression ratios.

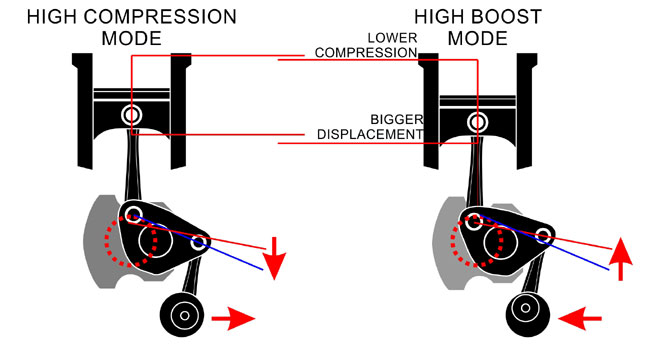

Nissan's VC-T varies the compression ratio from 14:1 (good for fuel economy and clean running) to 8:1 (good for extra turbo boost and extra power). There are other variable compression engines out there, but they are mostly experimental. Some use complex gears attached to the crankshaft or to eccentric bearings, others using tilting mechanisms that shorten the entire engine. Yes, that's as crazy as it sounds.

Peugeot's MCE-5 is the closest to Nissan's system. This uses an off-set piston attached to a fulcrum on the other side of crankshaft. Think of a bicycle foot-pump, where the arm pivots up and down on its hinge, sending power to the pump in the middle. Except in this case, the hinge can be moved to change the distance the pump arm moves, effectively changing compression.

Nissan's system is similar, but in a stroke of inspiration, Nissan's pivot point rocks back and forth. This looks complicated, but this ingenious system has multiple benefits.

The up-and-down motion of the piston is transferred to the crankshaft, as in a regular engine. But the side-to-side rocking usually transferred from the crank to the piston gets sent, instead, to the lower link on the other side. Even better, the multi-link offsets the piston downstroke so that the upper-link moves straight down on the power stroke.

This eliminates the side-to-side rocking of the piston on the power stroke that occurs on a regular engine, which causes extra stress and friction, robbing the engine of power. Nissan's multi-link engine actually experiences less stress during the power stroke, when pressures inside the engine are greatest.

The dual link set-up also eliminates the need for heavy balancer shafts, which other engines, including Peugeot's MCE-5, use to quell the vibrations caused by the moving pistons. The lower link balances out the piston assembly; both upper and lower links are shorter and lighter than a traditional connecting rod, and they experience lower speeds and stress than a traditional assembly.

As for the variable compression bit: By changing the angle of the multilink by rotating the control shaft—using a hydraulic arm—you move the pivot point of the multi-link, changing both compression ratio and displacement. As seen here, just a few millimeters of movement has a big effect, switching from high-boost high-power operation to high-compression high-efficiency using a simple hydraulic actuator.

While it looks complicated, Nissan's system allows the use of much lighter components due to the reduced stress, and isn't any more complicated than many variable valve timing and lift systems. Lightweight components also make it cheaper to build than some modern diesels, and not much heavier than a regular piston engine, despite the extra assemblies.

Will it be reliable? Will it be better than a regular gasoline engine? Only time will tell. Still, we've been using variable valve systems since the '80s, and they've proven fairly reliable. It's about time we applied the same kind of thinking to the reciprocating piston assembly. In chasing the ultimate in performance and fuel economy, manufacturers are going to have to be very innovative in the decades ahead.