It’s the upper steering-column housing. I’d been looking for a way into this story to try and encapsulate the astonishing attention to detail in a relatable way. So, here we go. As far as possible, when you order a car from Eagle—be it a restored Jaguar E-Type or a rebodied special like the Lightweight GT you see here—pieces are salvaged from an original car. The housing is probably rusty, so it’s aqua-blasted (not dry-blasted, as that’s too harsh), stripped back, made good. But after 35 years at this, and with a factory full of specialist craftsmen, Eagle knows more. It knows the mounting points where the housing connects under the dash flex and, in time, crack, so extra welds are put in to strengthen it.

It also knows that back when the E-Type was first made, Jaguar cut incision slots in the tube to make it easier to clamp tight against the plastic bushing through which the steering column itself rotated. But that plastic bushing is too soft, so it wears. Eagle replaces it with a tougher nylon part, and welds up then polishes back the unnecessary slots. To get the fit perfect, that nylon bush is reamed before it is pushed home. Eagle could commission new, improved parts from a supplier. It would probably be cheaper, but that’s not the point. The original part is re-engineered. It takes several hours.

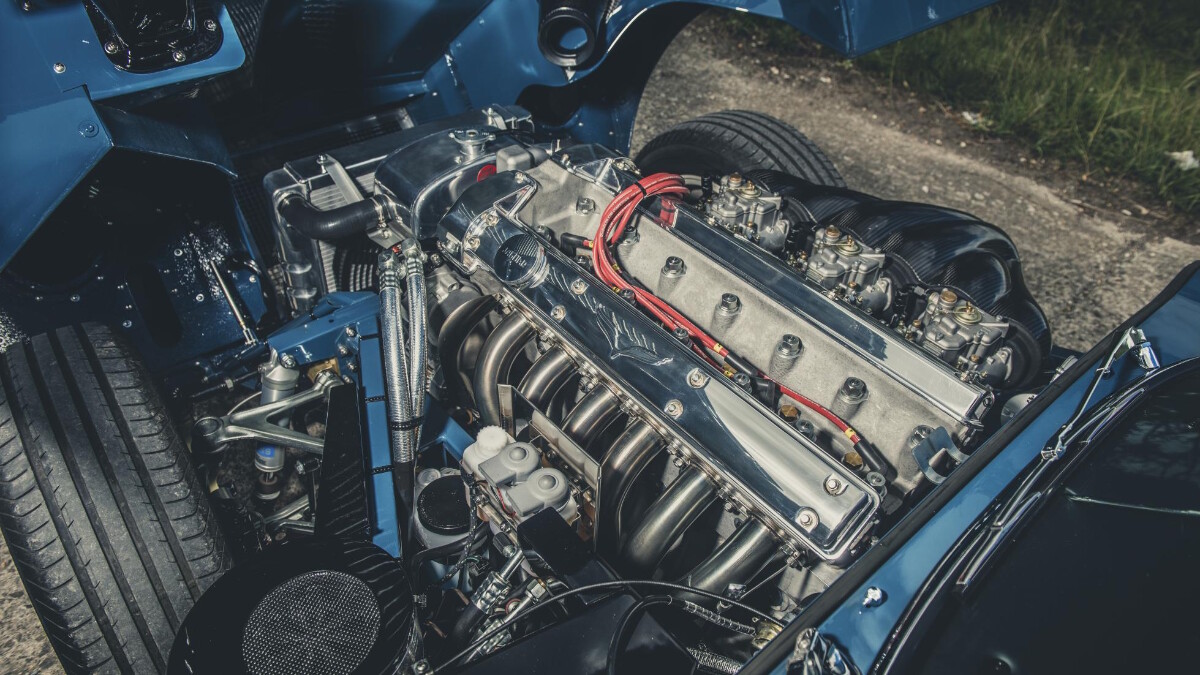

How many parts make up an Eagle E-Type? No one’s quite sure, but they’re all here, neatly laid out on racks, sitting in jigs, waiting on shelves or benches, ready to be carefully, diligently connected each to the other: valve springs, washers, sheets of aluminum, steering arms, wires. And if they’re not here already, they’re probably in the process of being created behind another door in the pristine yard of this tucked away farm.